Txhua Yam Koj Yuav Tsum Paub Txog Kev Txhaj Tshuaj Molding

Txhaj Molding yog dab tsi?

Txhaj Molding yog txheej txheem tsim khoom tsim khoom hauv ntim loj. Nws yog feem ntau siv nyob rau hauv cov txheej txheem tsim khoom loj uas tib feem yog tsim ntau txhiab lossis ntau lab lub sijhawm ua ntu zus.

Dab tsi yog cov polymers siv hauv kev txhaj tshuaj molding?

Cov lus hauv qab no teev qee cov khoom siv uas nquag siv:

Acrylonitrile-Butadiene-Styrene ABS.

Nylon PA.

Polycarbonate PC.

Polypropylene PP.

Polystyrene GPPS muaj.

Cov txheej txheem ntawm kev txhaj tshuaj molding yog dab tsi?

Cov txheej txheem yas txhaj tshuaj molding ua rau ntau qhov chaw ntawm cov khoom zoo nrog qhov tseeb, nrawm heev. Cov khoom siv yas nyob rau hauv daim ntawv ntawm granules yog yaj kom txog thaum muag muag txaus los txhaj rau hauv lub siab kom sau ib lub pwm. Qhov tshwm sim yog tias cov duab tau muab luam tawm raws nraim.

Lub tshuab txhaj tshuaj molding yog dab tsi?

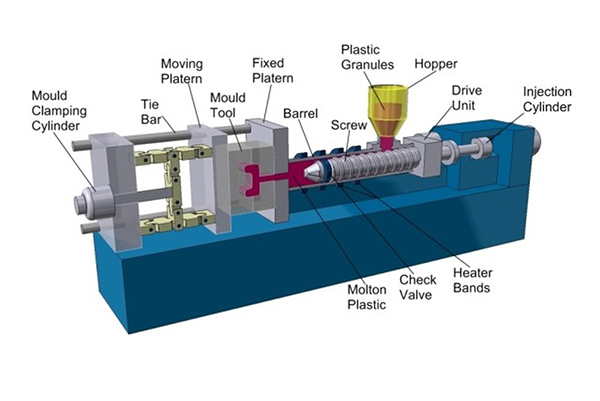

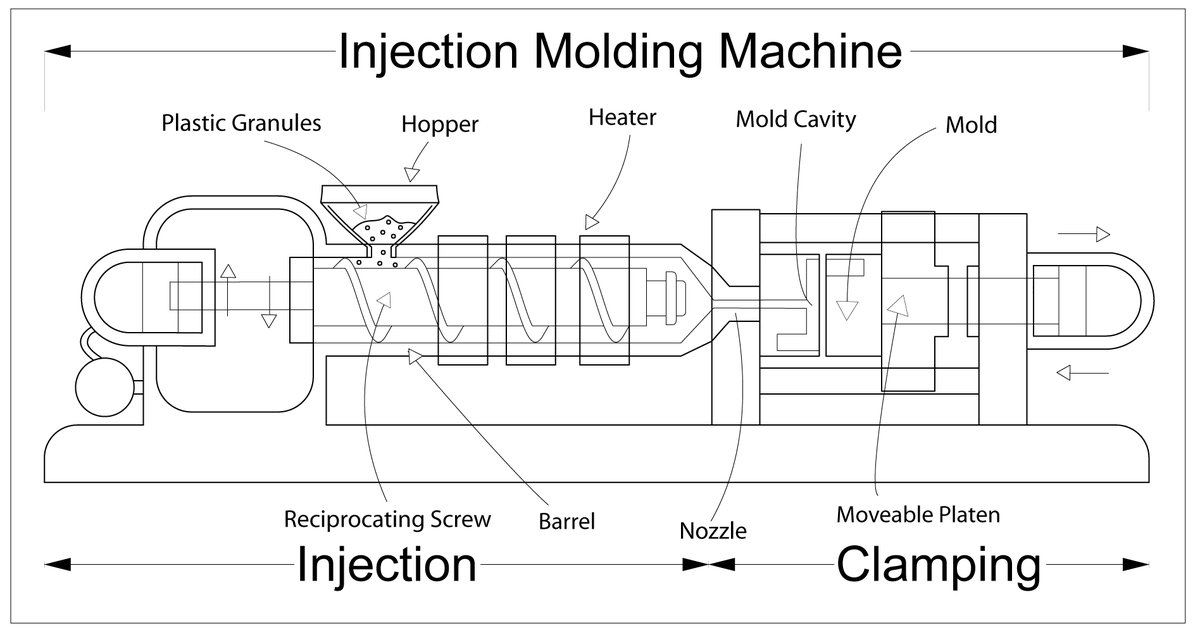

Lub tshuab txhaj tshuaj molding, lossis (Kev txhaj tshuaj molding tshuab BrE), tseem hu ua kev txhaj tshuaj xovxwm, yog lub tshuab tsim cov khoom yas los ntawm cov txheej txheem txhaj tshuaj molding. Nws muaj ob qhov tseem ceeb, ib qho kev txhaj tshuaj thiab ib chav clamping.

Kev txhaj tshuaj molding tshuab ua haujlwm li cas?

Cov khoom granules rau ib feem yog pub los ntawm lub hopper rau hauv ib lub thoob rhuab, melted siv lub rhaub bands thiab kev sib txhuam ntawm ib tug reciprocating ntsia hlau chim. Cov yas yog tom qab txhaj tshuaj los ntawm lub nozzle rau hauv pwm kab noj hniav qhov twg nws txias thiab hardens rau configuration ntawm kab noj hniav.

Dab tsi yog qee qhov kev txiav txim siab rau Kev Txhaj Tshuaj Molding?

Ua ntej koj sim ua ib feem ntawm kev txhaj tshuaj molding xav txog ob peb yam hauv qab no:

1, Kev txiav txim siab txog nyiaj txiag

Tus nqi nkag: Kev npaj cov khoom lag luam rau kev txhaj tshuaj molded tsim yuav tsum tau nqis peev ntau. Nco ntsoov tias koj nkag siab qhov tseem ceeb ntawm qhov no ua ntej.

2, Ntau Lawm

Txiav txim seb tus naj npawb ntawm cov khoom tsim los ntawm kev txhaj tshuaj molding ua tus nqi zoo tshaj plaws ntawm kev tsim khoom

Txiav txim siab tus naj npawb ntawm cov khoom uas koj xav tias yuav tawg txawm tias koj cov peev txheej (xav txog cov nqi ntawm kev tsim, kev sim, kev tsim khoom, kev sib dhos, kev lag luam, thiab kev faib khoom raws li tus nqi xav tau rau kev muag khoom). Tsim nyob rau hauv ib tug conservative margin.

3, Kev txiav txim siab tsim

Tshooj Tsim: Koj xav tsim ib feem ntawm ib hnub nrog kev txhaj tshuaj molding hauv siab. Simplifying geometry thiab txo tus naj npawb ntawm cov ntu thaum ntxov yuav them nyiaj faib rau hauv txoj kev.

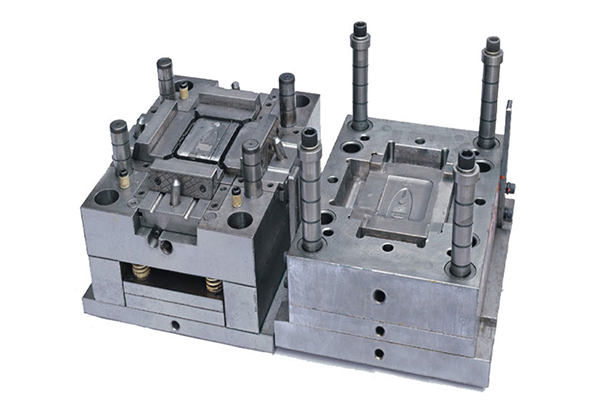

Tool Tsim: Nco ntsoov tsim cov cuab yeej pwm kom tsis txhob muaj qhov tsis xws luag thaum tsim khoom. Rau ib daim ntawv teev npe ntawm 10 qhov kev txhaj tshuaj molding tsis xws luag thiab yuav ua li cas kho lossis tiv thaiv lawv nyeem ntawm no. Xav txog qhov chaw ntawm lub rooj vag thiab khiav simulations siv moldflow software zoo li Solidworks Plastics.

4, Kev txiav txim siab ntau lawm

Lub Sijhawm Cycle: Txo lub sijhawm voj voog tsawg kawg nkaus raws li qhov ua tau. Siv cov cav tov nrog kub khiav tshuab yuav pab raws li yuav zoo-xav-tawm tooling. Cov kev hloov me me tuaj yeem ua rau muaj qhov sib txawv loj thiab txiav ob peb lub vib nas this los ntawm koj lub sijhawm voj voog tuaj yeem txhais ua cov nyiaj khaws cia loj thaum koj tsim ntau lab qhov chaw.

Assembly: Tsim koj qhov chaw kom txo qis kev sib dhos. Ntau qhov laj thawj kev txhaj tshuaj molding yog ua tiav nyob rau sab hnub tuaj Asia yog tus nqi ntawm kev sib dhos yooj yim thaum lub sijhawm txhaj tshuaj molding khiav.

Post lub sij hawm: Nov-05-2020